Automatic Feeding System- Loss in weight Dosing System

| Type | Dosing Range kg/hr | Applicable for |

| GDM1 | 100-400 kg/h | Pellets(GPPS material) |

| GDM2 | 100-400 kg/h | Pellets(GPPS material) |

| GDM3 | 100-400 kg/h | Pellets(GPPS material) |

| GDM4 | 4-50 kg/h | Pellets(fire resistant material) |

| GDM5 | 4-50 kg/h | Pellets(Color Masterbatch) |

| GDM6 | 1.5-30 kg/h | Powder(Talcum Powder) |

Applicable for the twin screw and automatic & large scale XPS machine;

Flexible Connection to hopper ,which is integrated with air-discharge and filtering device;

Interlock with extruder;

Automatic precise dosing;

Easy adjustment of materials proportion

Flexible Connection to hopper ,which is integrated with air-discharge and filtering device;

Interlock with extruder;

Automatic precise dosing;

Easy adjustment of materials proportion

| Technology data |

| Weightless Control Module GE/CN II; Weight Sensor: MT1260; Motor Control Module VFD015E43A Interface C2 Touch |

Automatic Feeding System- Vacuum Inhaling System

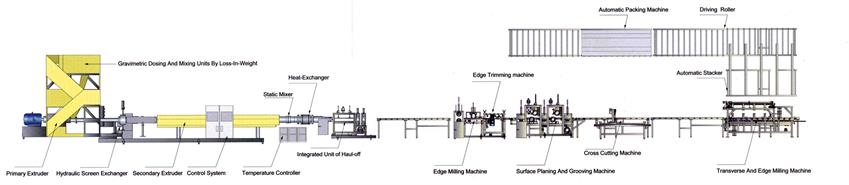

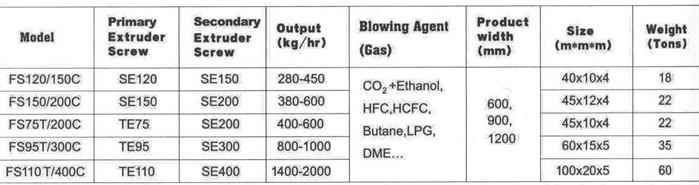

Co2-XPS Foam Board Production Line- parallel Twin Screw

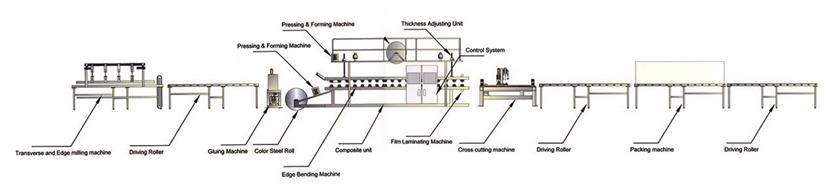

Double Surface color Steel Sandwich Panel Production Line Special for XPS Foam Board

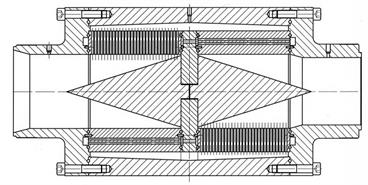

Hydrulic Screen Exchanger

Hydraulic Screen Exchanger

· Oil hydraulic driven

· Fore and post pressure sensor included

· Cycling screen changer

· Non-stop design

· Stable Pressure

· Reliable

· Oil hydraulic driven

· Fore and post pressure sensor included

· Cycling screen changer

· Non-stop design

· Stable Pressure

· Reliable

Hydrulic Exchanger

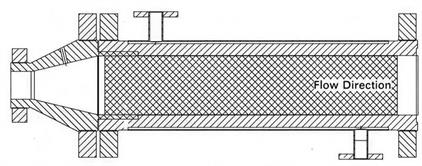

Heat-Exchanger

After going through Heat-Exchanger, Melt Mass mix thoroughly to reach even final temperature.

This helps polystyrene expand better and more uniform. Hence, low density is ensured.

After going through Heat-Exchanger, Melt Mass mix thoroughly to reach even final temperature.

This helps polystyrene expand better and more uniform. Hence, low density is ensured.

| Model | HE150/ HE200/ HE300/ HE400 |

| Cooling Method | Oil Cooling |

| Oil Temperature Controller |

Cooling Media: Heat-conduct Oil Temperature Range: up to 180°C Heating Power: 9 KW Temperature Precision: ±0.1°C |

Static Mixer

Static Mixer

After going through Static Mixer, Melt Mass have uniform material temperature, color and viscosity. In this case, product quality and beautiful appearance are ensured.

After going through Static Mixer, Melt Mass have uniform material temperature, color and viscosity. In this case, product quality and beautiful appearance are ensured.

| Model | SM 150/ SM200/ SM300/ SM400 |

| Mixing Section Length | 4D |

| Working Principal | While Mixing Section is fixed, Melt Materials are stirred and mixed automatically. |

| Characteristics |

· Excellent Homogenization Uniform Material Temperature Uniform Material Color Uniform Viscosity · Excellent Product Appearance & Quality |

Slot Die

| Model | SD300/SD450/SD600 |

| Principal |

Distance between Dfe Lips: 0.5-1.5mm By adjusting the distance, different product thickness will be reached. |

| Advantages |

Easy Adjusting Stable Pressure-drop. |

Slot Die

The special channel inside of Slot Die makes melt materials flow out easily, which ensures stable Pressure Drop.

The special channel inside of Slot Die makes melt materials flow out easily, which ensures stable Pressure Drop.

Calibrator

| Model | Name |

| EHC-800 | Electric Heating Calibrator (1400*800mm) |

| EHC-1200 | Electric Heating Calibrator (1400*800mm) |

| OHC-800 | Oil Heating Calibrator (1400*800mm) |

| OHC-1200 | Oil Heating Calibrator (1400*1200mm) |

Calibrator

| Item | Parameters |

| Lifting Motor | 1.5KW*2 |

| Driving Motor |

0.75KW |

| Heating Power |

9KW |

| Material of cover plate |

PTFE |

Haul-off Unit

Haul-off Unit

| Item |

Parameters |

| Motor | 3KW Inverter Control |

| Roller Specification | ¢275x1400mm |

| Up-roller driving method | Pneumatic |

Lengthwise Edge Milling & Trimming Unit

| Working Principal |

XPS board is pulled to this machine firstly; then after being processed via fixing device, the edges will be milled into required dimension, and meanwhile powder is inhaled by Central Dust Collecting Unit . Through trimming machine, the shape of Ship-lap is achieved.(lf trimming is not required, cutting blade will be put away). |

Lengthwise Edge Milling & Trimming Unit

Double Surface Planing & Grooving Machine

| Working Principal |

Surface planing & grooving are processed simultaneously. Planing tool is made of alloy blades which are positioned besides the XPS Foam. Surface grooving cutter is disposable alloy blade, and groove depth is easily adjusted. There are fixing devices at two ends of the machine to avoid vibration |

Double Surface Planing & Grooving Machine

Automatic Stacking System

| Item | Parameters | |

| Stacking width |

mm | A: 600, 8:1200 |

| Stacking height | mm | 520 |

| Motor | Servo motor | |

| Sensor | Infrared sensor | |

| Dimensions (L x W x H)(approx.) | m | 5.0 x 5.5 x 1.1 |

Automatic Stacking System

Automatic Stacking System is fully automatic, greatly improving the stacking efficiency.

It could process 2 stacks at the same time. Servo motor controls ascending & descending steadily. Precise electrical control parts guarantee the accuracy and assure that the equipment runs for a long time.

Automatic Stacking System is fully automatic, greatly improving the stacking efficiency.

It could process 2 stacks at the same time. Servo motor controls ascending & descending steadily. Precise electrical control parts guarantee the accuracy and assure that the equipment runs for a long time.

Length Cutting Machine (Alloy Blade)

Length Cutting Machine (Alloy Blade)

| Item | Parameters |

| Cutting Thickness | 20mm-100mm |

| Cutting Width | 600mm |

| Cutting Length | ≥1180mm |

| Driving motor Length* Width |

2.2KW 380V 50HZ Inverter 2500mm*1500mm |

Automatic Packing System

Automatic Packing System

| Item | Parameters |

| Type | Enclosed |

| Packing width | 600mm |

| Packing Length | 900 mm /1000 mm /1200 mm |

| Maximum Thickness | 660 mm |

| Packing Material | PE shrinkage film |

| Sensor | Infrared sensor |

| Power | 40KW |

| Dimensions (L x W x H) | 20.0 x 2.2 x 2.4 m |

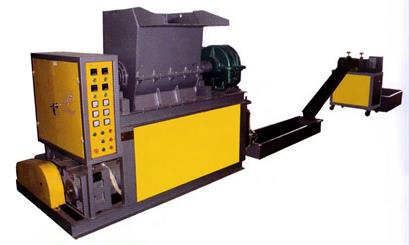

Recycling & Granulating System

| Item | Parameters |

| Material | Margin of XPS / EPS |

| Crush Power | 11 KW |

| Screw Diameter | φ75 mm |

| Material of Screw | 38CrMoALA |

| Heating Power | 26KW |

| Motor Power | 7.SKW |

| Cooling water tank Length | 1.8 m |

| Pelletizer power | 3KW |

| Dimensions (L x W x H) | 7.0 x 1.2 x 1.5 m |

Recycling & Granulating System

Recycling & Granulating System crush the off-cuts of XPS board, and recycle it into GPPS granules. The system is in integrated design, easy to operate and maintain. The system control the recycling temperature accurately, to reach the best quality of recycled GPPS granules

Recycling & Granulating System crush the off-cuts of XPS board, and recycle it into GPPS granules. The system is in integrated design, easy to operate and maintain. The system control the recycling temperature accurately, to reach the best quality of recycled GPPS granules

Powder Recycling & Granulating System

| Item | Parameters |

| Material | Powder of XPS / EPS |

| 1st Screw Diameter | φ120 mm |

| 1st Motor | 37KW |

| 2nd Screw Diameter | 38CrMoALA |

| 2nd Motor | 26KW |

| Material of Screw | 38CrMoALA |

| Cooling water tank Length | 1.8 m |

| Pelletizer power | 2.2KW |

| Dimensions (L x W x H) | 7.0 x 1.2 x 1.5 m |

Powder Recycling & Granulating System

Powder Recycling & Granulating System is our latest design, with 2-stage screw extruders. It has large and stable output, and it is easy to operate and maintain. The screen change is driven by motor, easy and efficient to change the filter screen. The system controls the recycling temperature accurately, to reach the best quality of recycled GPPS granules.

Powder Recycling & Granulating System is our latest design, with 2-stage screw extruders. It has large and stable output, and it is easy to operate and maintain. The screen change is driven by motor, easy and efficient to change the filter screen. The system controls the recycling temperature accurately, to reach the best quality of recycled GPPS granules.

Centeral Dust Collecting System