- XPS Foam Insulating Board Extrusion Line

- XPS Cups Molding System

- Foam Sheet Extrusion Line

- Plastic Sheet Extrusion Line

- Two-Station Post Trim Thermoforming Systems

- DCR Reclaim Line

- IRD Crystallizing & Drying System

- MT Tilting Thermoforming Machine

- Contact Heating Thermoforming Machine

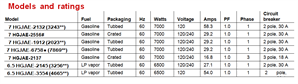

- Commercial generator set Quiet Gasoline

- Home

- Other Products

- Generator

- Gas Gen

All three Broadcrown CHP units were housed in custom-designed acoustic enclosures, built on site, to achieve a noise level of 80 dB[A] at 1 metre. A particular design challenge was to fit the units into the cramped conditions of the plant room, allowing for hot air discharges from the enclosures to leave the boiler house via a common duct. To avoid the possibility of noise and heat recirculation, dampers were fitted to the connections between each CHP unit and its discharge duct

Case History

Riverside Sewage Treatment Works

Riverside Sewage Treatment Works

Supply:

Cummins QSV91 lean-burn gas engines powering three generator sets

Application:

Biogas Combined Heat and Power project, to power a wastewater treatment works and provide heat for the site’s processes

Cummins QSV91 lean-burn gas engines powering three generator sets

Application:

Biogas Combined Heat and Power project, to power a wastewater treatment works and provide heat for the site’s processes

Cummins engines at the heart of cogeneration solution for London wastewater treatment plant

Thames Water Utilities Ltd is the UK’s largest water and wastewater services company. Every day it supplies 2.6 billion litres of drinking water from 100 water treatment works through 32,000 km of managed water mains to 8.7 million customers across London and the Thames Valley. And every day it removes and treats 4 billion litres of wastewater from 13.8 million customers through 108,000 km of managed sewerage mains to

349 sewage treatment works across an extensive tract of southern England.

In 2008 Thames Water invited tenders for a sludge digestion project at one of its major sites, Riverside Sewage Treatment Works in London. The tender was won by UK company Broadcrown Ltd,

a leading independent manufacturer of power generators and generation systems from 6 kVA through to +30 MVA. It was Broadcrown’s task to design and supply a cogeneration solution that would use biogas to power the site and provide heat for the site processes

Thames Water Utilities Ltd is the UK’s largest water and wastewater services company. Every day it supplies 2.6 billion litres of drinking water from 100 water treatment works through 32,000 km of managed water mains to 8.7 million customers across London and the Thames Valley. And every day it removes and treats 4 billion litres of wastewater from 13.8 million customers through 108,000 km of managed sewerage mains to

349 sewage treatment works across an extensive tract of southern England.

In 2008 Thames Water invited tenders for a sludge digestion project at one of its major sites, Riverside Sewage Treatment Works in London. The tender was won by UK company Broadcrown Ltd,

a leading independent manufacturer of power generators and generation systems from 6 kVA through to +30 MVA. It was Broadcrown’s task to design and supply a cogeneration solution that would use biogas to power the site and provide heat for the site processes

The process required a continuous supply of 4 MWe of power. To provide this, three Broadcrown Combined Heat and Power (CHP) units were installed, each equipped with Cummins QSV91 lean-burn gas engines and Cummins Generator Technologies STAMFORD® alternators. Cummins QSV91 heavy-duty engines were the ideal choice to power Broadcrown’s CHP units. The 4-cycle, water-cooled QSV91 engine offered crucial advantages. It is not only highly fuel efficient, it also reduces NOx exhaust emissions.

Fully automatic electronic management and a sophisticated engine monitoring system add to its attractions.

Fully automatic electronic management and a sophisticated engine monitoring system add to its attractions.

The 4-cycle, water-cooled QSV91 engine offered crucial advantages. It is not only highly fuel efficient, it also reduces NOx

exhaust emissions.

exhaust emissions.

Broadcrown’s design for the project also involved fire protection through a water mist system, jacket water heat recovery, a full header tank system, standby generators, and a control system to interface with the site-wide power management system. When

all the work was done, Thames Water’s Riverside Sewage Treatment Works had an efficient and

cost-effective cogeneration solution, with Cummins QSV91 engines at the heart of it.

all the work was done, Thames Water’s Riverside Sewage Treatment Works had an efficient and

cost-effective cogeneration solution, with Cummins QSV91 engines at the heart of it.